Multifast® batch feeding system

Multifast batch feeding system for pig houses

Multifast® is a batch feeding system for pig houses. It controls and connects the feed processes at your pig farm: from the moment the feed leaves the bin, to the delivery of the feed to the pigs. All feed passes through a special weigher-mixer that can mix up to 20 ingredients. It also weighs the batches with precision and sends them to the correct troughs or day bins at the house.

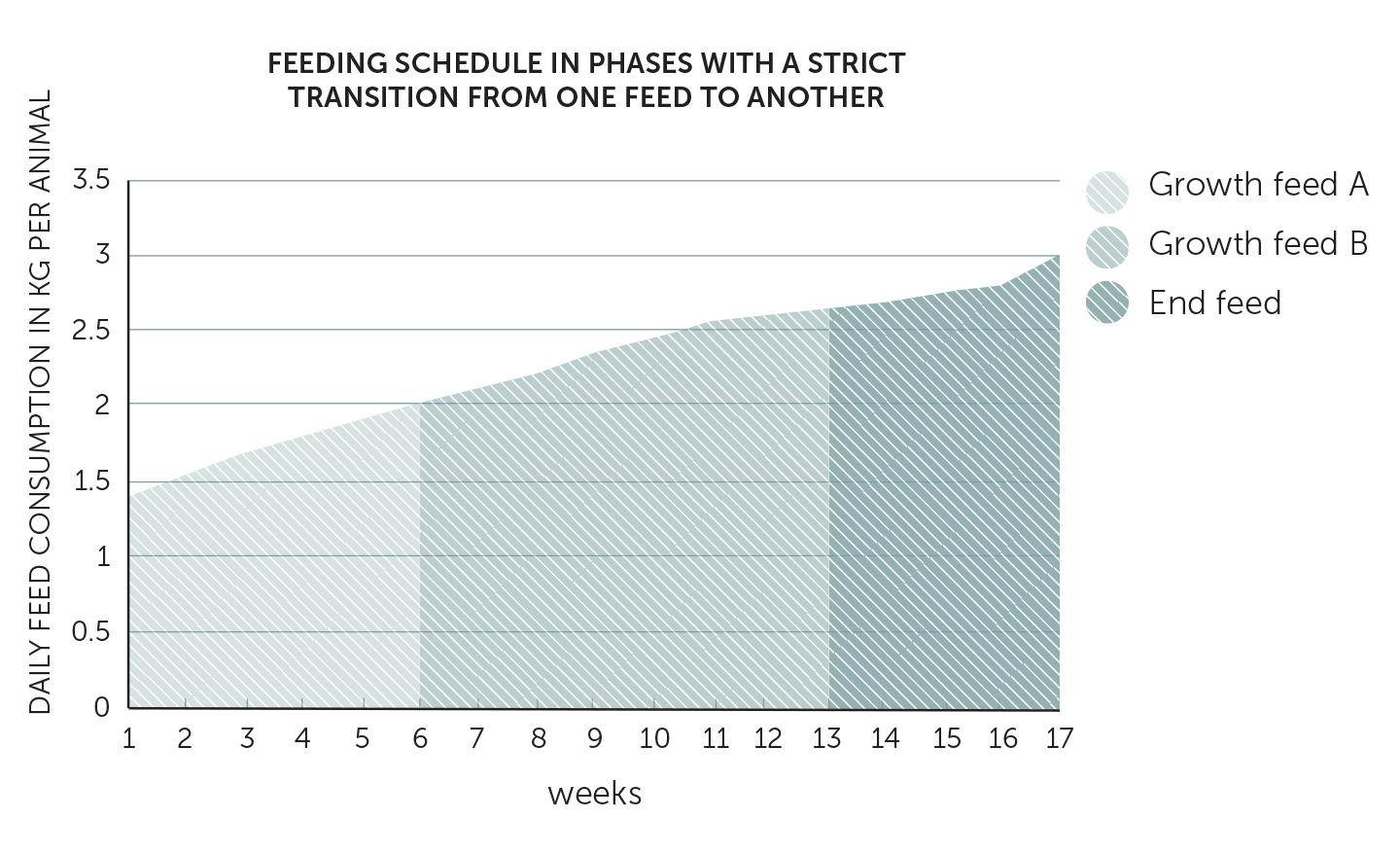

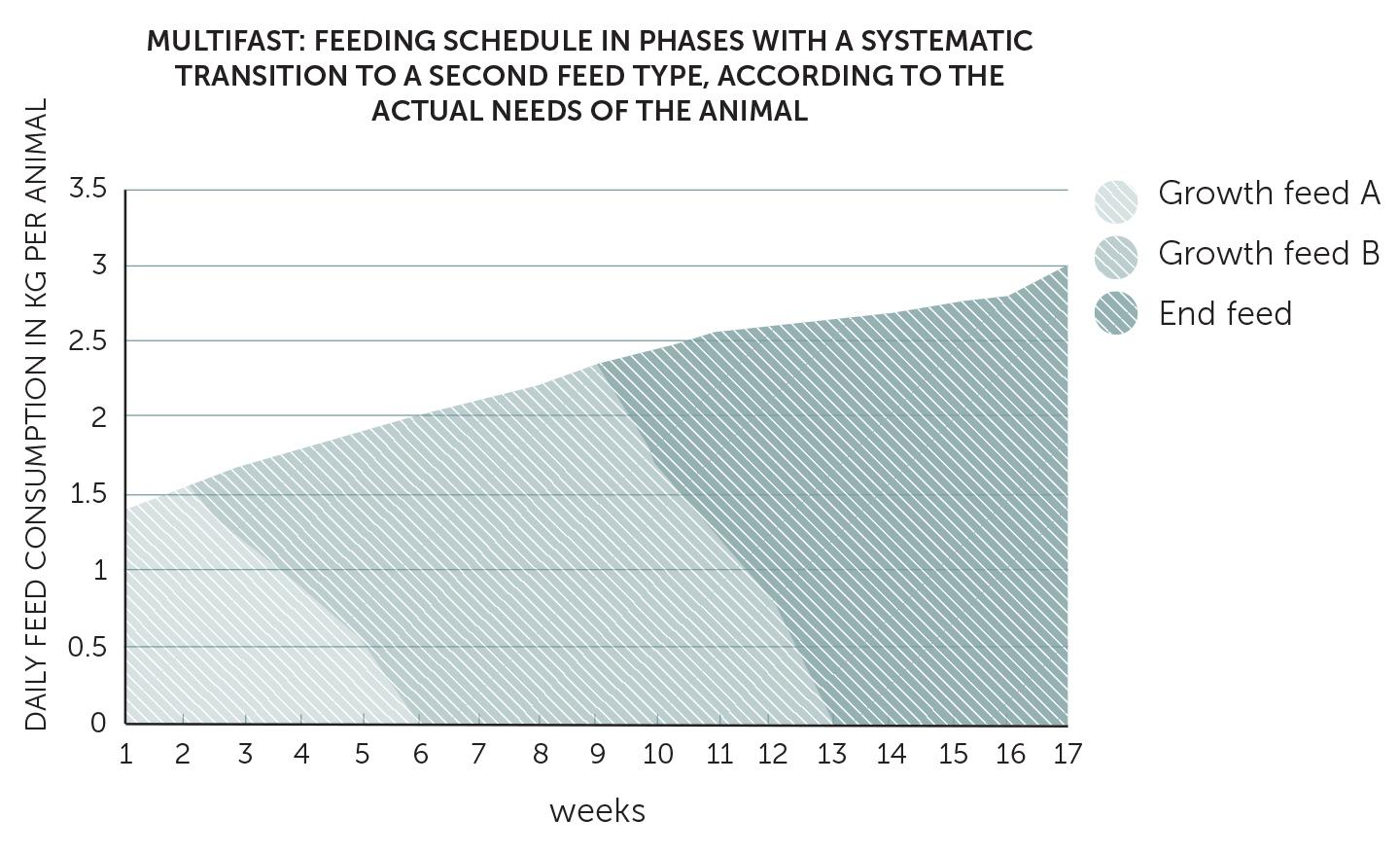

Feeding in phases with your own ingredients

Multifast’s strength is in the fact that it feeds in phases. The transition from one type of feed to another is made gradually in phases. This is advantageous for your feed expenditure. However, it is also an important feature due to the fact that pigs are creatures of habit. Pigs often need time to adjust to a new flavor or texture in their feed. When the transition is made gradually, they don’t notice the difference, which means their eating process can continue unencumbered.

A second reason why Multifast can add value to your pig company is the option to use self-produced raw materials. If you mix your own feed, you can decide which feed components to use. Generally speaking, the ingredients you use in your own mix are cheaper. This means that you can quickly earn back your investment in the Multifast batch feeding system.

Finally, you can adjust the feed composition at any time. If you know the actual needs of the pigs, you can change the composition and quantity of the feed whenever you want with Multifast. A tailored feed process that gets results.

A Multifast system consists of a set of Roxell products that initiate and control the feeding process.

- Multifast handles the weighing, mixing and transportation of very accurately measured batches of feed.

- Multifast feeds in phases to provide a systematic transition to a different type of feed. You can feed much more precisely, according to the actual needs of the animal.

- The system is basically a feed kitchen. You decide which feed components to use. Mix raw materials that you have produced yourself and supplement them with pre-mixed feed to create the right composition.

The components

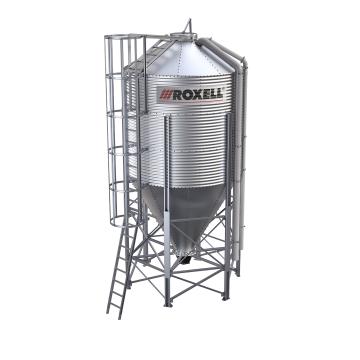

- Storage bin

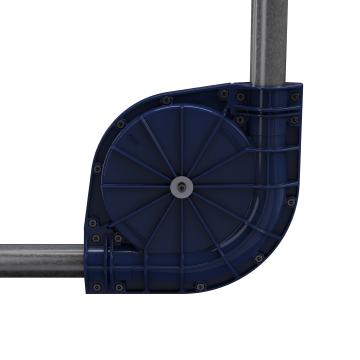

feed bins should preferably be kept on the street side of your site to ensure biosecurity, just outside the fence, or they should be able to be filled from a distance - Flex-Auger™ or Discaflex™ feed transport tubes

a feed transport network that moves large volumes of feed in a short time frame - Weigher-mixer

selects and weighs the ingredients with high accuracy: up to 20 different ingredients. Available in two versions:- 100 l weigher-mixer that can be set for a batch of up to 50 kg (110 lb)

- 200 l weigher-mixer that can be set for a batch of up to 100 kg (220 lb)

- Automatic outlet

the final step before the feed drops into the day bin or reservoir of the trough. A Roxell product with a very good reputation. Praised due to its smooth feed outflow and reliability.

Solution for biosecurity

There is a clear trend in the livestock sector towards a structural incorporation of biosecurity measures into everyday operations. With Multifast, you can make significant improvements. The system handles the feed transport at the site and allows deliveries of feed to be made outside the walls of the company. All transport is carried out overhead.

Investment in precise feeding

When taken together, the cost savings and additional yield mean that you can easily recoup the investment in a Multifast feeding system in one year.

Precise feeding in phases with cheaper raw materials and no decline in results:

- Low feed costs — less concentrated starter feed and pre-mixes

- Use your own raw materials

- Less manure

- Better feed conversion

- Increased biosecurity

- Time savings