South Korea's No. 1 broiler breeder producer uses proven Roxell products on all their farms

Sam Hwa GPS Breeding Agri., Inc. is a third-generation family run breeder company with 70 years’ history. They are now the No.1 broiler breeder producer in Korea operating 11 farms and 3 hatcheries. To keep the best outcomes, they always use the best facility in their production sites. SamHwa uses proven Roxell products on all their farms. Because they used Roxell's products for 30 years, every farm staffs are familiar with Roxell’s products and can handle those skillfully no matter which SamHwa’s farm they go to.

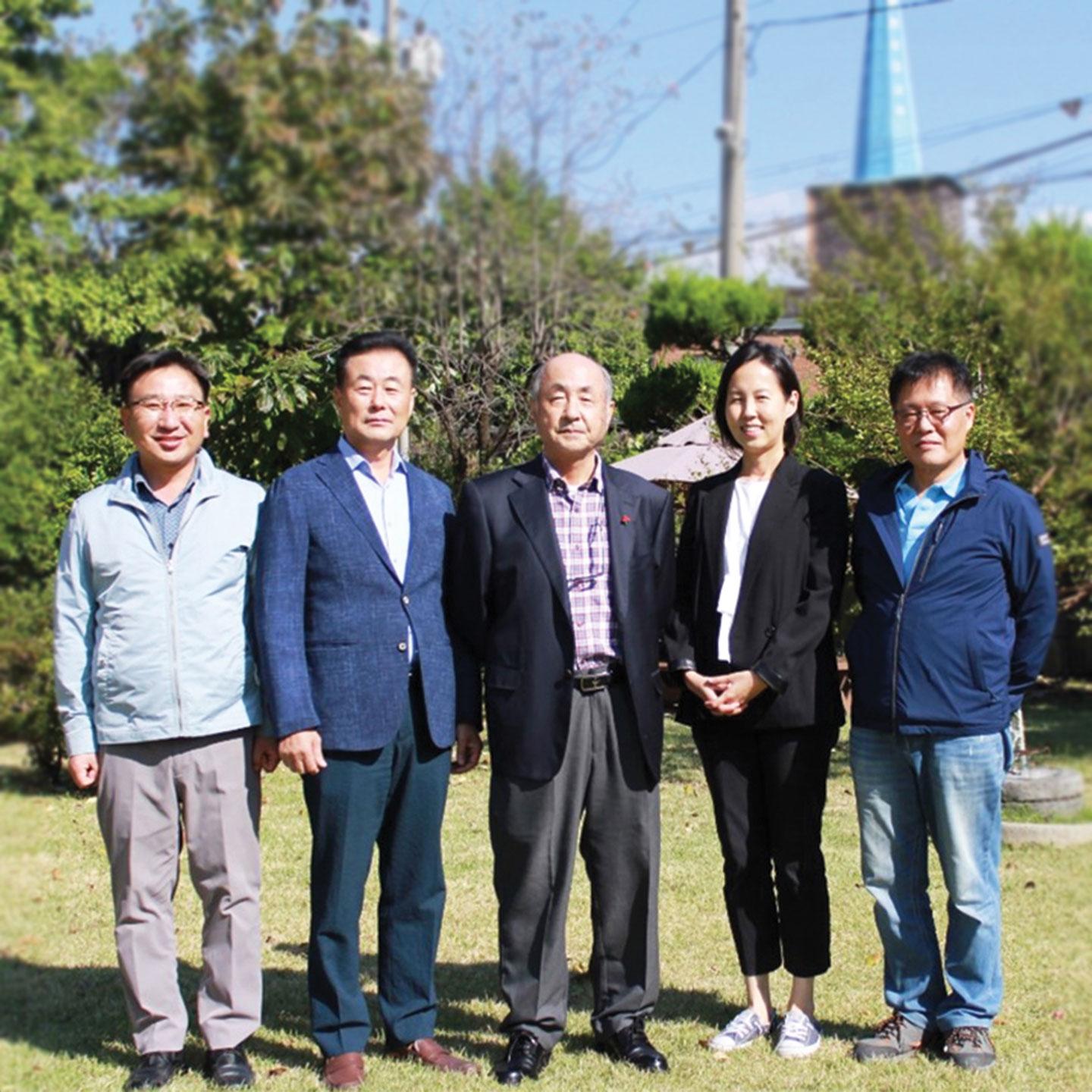

From left to right: Dr. Jong-su Ha, Dr. Sang-bae Lee, Mr. Sung-Hwang Bae (Chairman), Mrs. Sang-Hyeon Bae and Mr. Young-Hio Ko.

Currently, SamHwa is the No. 1 broiler breeder producer in Korea operating 11 farms and 3 hatcheries. With 300,000 broiler breeders, they also produce annually 50 million broiler chicks. As other businesses, they have pig farms and organic fertilizer companies processing animal manure. Why do integrated broiler companies want to get chicks from Samhwa? Because their productivity is the best in Korea. For example, while Ross’ standard chick production number per female bird is around 150 chicks, SamHwa has been producing more than 160 chicks for a long time. As SamHwa’s chick quality is also the best, many integrated companies prefer to use SamHwa’s, rather than producing breeder chicks by themselves.

If we see SamHwa’s 70-years of history, we can see the history of the Korean broiler industry as well. The founder of SamHwa, the father of the current president, started layer hatchery in 1952. Since there was no incubator in Korea at that time, he had to hatch eggs completely by manual, including temperature adjustment and egg turning. In 1975, the current president changed his business from layer hatchery to broiler hatchery. Before 1970, chicken meat came from finished old layers, not from broiler breeders. The 1970s was a period of full-fledged economic growth in Korea.

With the increasing demand for chicken meat, SamHwa could grow its business also. As many competitors expanded similar businesses, in 1989, Samhwa decided to first introduce grandparents’ stock(GPS) in Korea. Since the 1990s, the Korean broiler industry turned from the traditional way to modernized integrated business. Integrated companies wanted hygienic and good-quality breeders for their stable business operations. With that trend, SamHwa could expand their farms and hatcheries. As many developing Asian countries started broiler business in the late 1990s, SamHwa exported their breeder chicks to six Asian countries until the 2003 national HPAI outbreaks in South Korea.

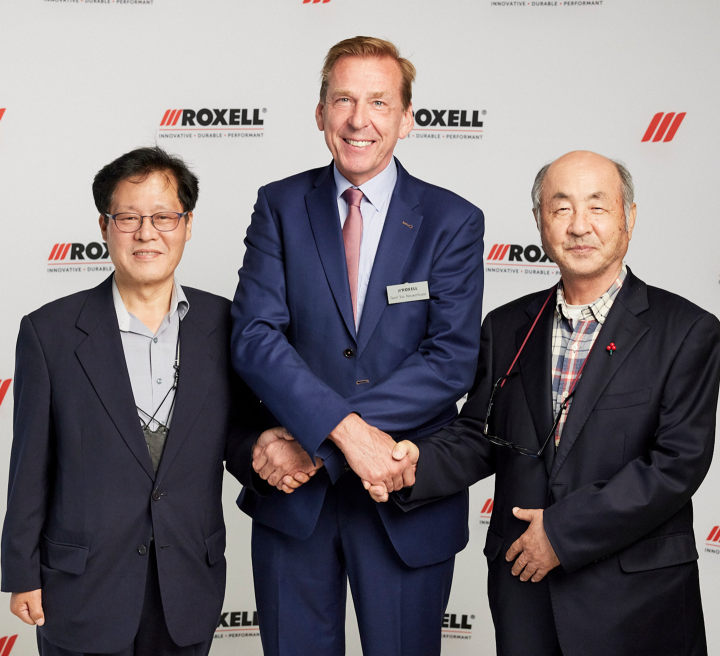

Modern farms rely heavily on automation. If someone uses unreliable equipment or fails to repair problematic equipment quickly, they will suffer huge economic losses. SamHwa uses proven Roxell products on all their farms. Because they used Roxell's products for 30 years, every farm staffs are familiar with Roxell’s products and can handle those skillfully no matter which SamHwa’s farm they go to. There is an experts and spare parts center in Samhwa’s facility equipment department. When there is a problem, they promptly identify the cause and solution.

Even if it is an unfamiliar problem, they are accustomed to getting Roxell’s professional support and solving them, with excellent technical support from Roxell. As they are using the same equipment system, it is easy to secure and store spare parts.

Since 2018, it is on the process of succession of the family business to the third generation. Although she will take over the No.1 breeder company, she knows management won’t be merely enjoyable as there will be a lot of new challenges in her generation. Now in Korea, the livestock industry is considered not only conventional but also a non-ecofriendly business. Recently SamHwa began a project to generate eco-friendly power using methane gas from livestock waste. They are trying to be reborn as a company that provides eco-friend solutions against pollution from the livestock industry. SamHwa has proven that success comes from a challenge to advance.