Baramati Agro poultry farm uses iQon™ controller in India

"iQon gives me peace of mind because everything is automatic: our broiler breeders eat their rations according to the schedule, feed lines winch up automatically and feed curves adjust the feed volume."

iQon™ – Roxell’s controller for poultry houses – is also used within integrations in India such as Baramati Agro Ltd. This poultry company answers seven questions about iQon.

Question 1: Your poultry farm in India works for Baramati Agro. What are your activities?

Dr. Mahadeo Awale: “I am the Farm Manager on a broiler breeder farm that is owned by Baramati Agro Ltd, which is a major agribusiness company in India. Initially they specialized in chickens and meat processing, but now Baramati Agro also produces sugar, ethanol, fruit, vegetables, dairy products etc.”

“My poultry company has nine houses for broiler breeders. The rearing and production periods — from day-old chicks to the final lay — take place in the same house. Per house, there are 9000 females and 900 males.”

Question 2: Why did Baramati Agro opt for the iQon feed computer from Roxell?

Dr. Mahadeo Awale: “Because Roxell and its Indian installer Polaris Equipment Pvt. guarantee good support. Security and continuity are two important criteria for us because the controller runs my company. With iQon, I have the stability I was looking for. Roxell also regularly offers software updates and the upgrades often contain new features, which is interesting.”

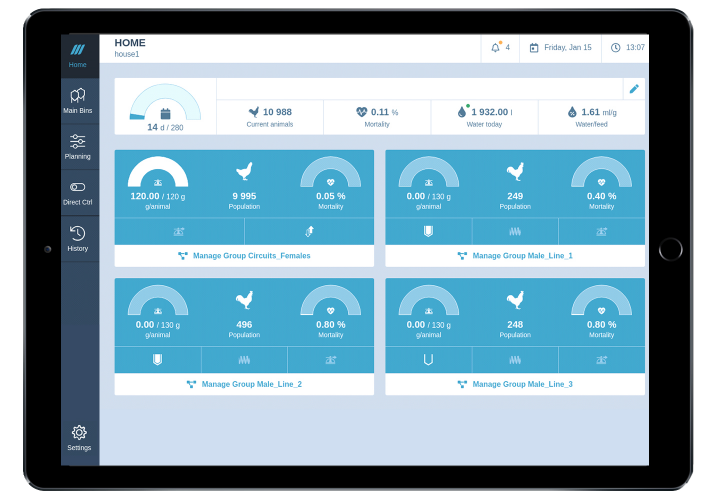

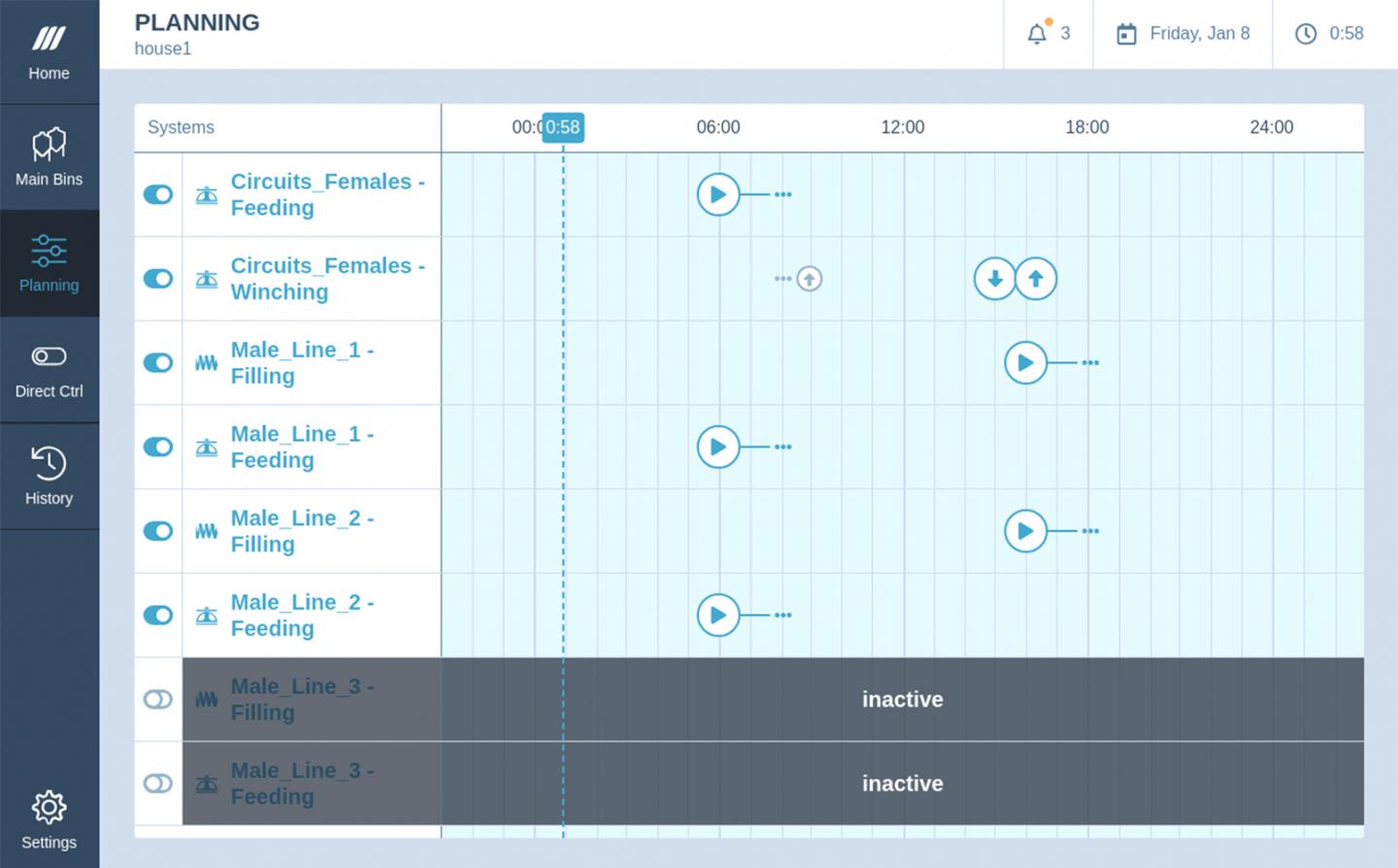

“My iQon does more than just deliver precise feed amounts to the right place. In addition to scheduling the feeding times, I can also create a schedule for winching up the feed lines. iQon knows when the drop tube of the transport system is empty and only starts winching up when it’s safe to slide the tubes inside each other. The system gives me peace of mind because I know that the conditions in the house are optimal before, during and after feeding.”

Question 3: Do you also control iQon remotely?

Dr. Mahadeo Awale: “Roxell’s Area Sales Manager explained that I can control the computer remotely with the ‘iQon #Sharp’ module using a smartphone or tablet. It’s a very handy feature because it allows me to monitor the activity at the poultry company even when I’m not there. Another useful feature is that the service team can log in to my iQon to carry out the upgrades and provide support without coming to my company.”

Question 4: What are the most important advantages of iQon, in your experience?

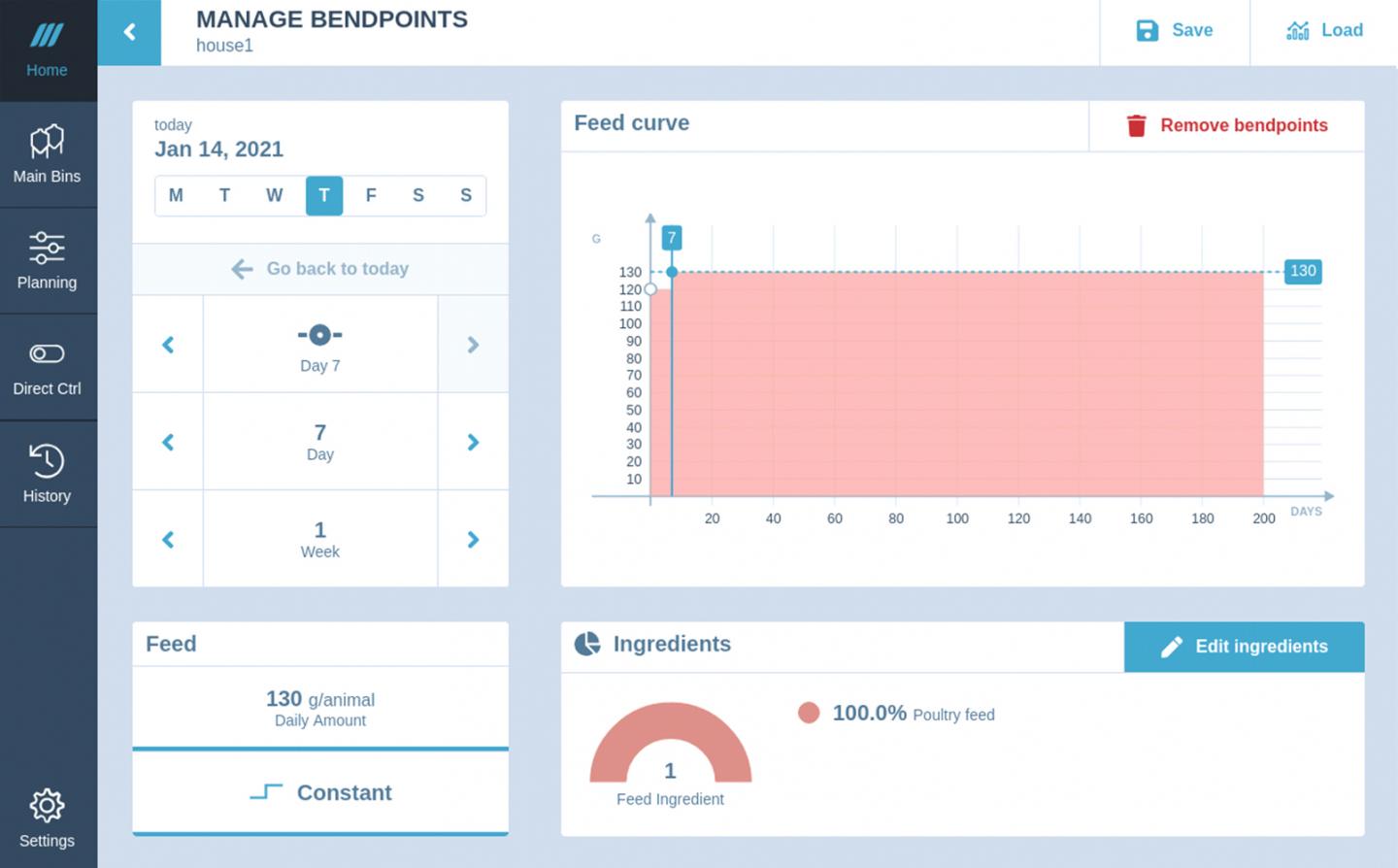

Dr. Mahadeo Awale: “I have a feed strategy for my broiler breeders and iQon can implement that strategy with the utmost accuracy. I can set very precise feed amounts for each feeding moment and I can specify exact times. And, as I mentioned earlier, you can create schedules to automatically winch up the feed circuits.”

Question 5: How easy is it to use the iQon controller?

Dr. Mahadeo Awale: “The interface is very user friendly. On the control panel, there is a touchscreen that displays the house layout at my company. This makes it easy for me to find the information I need, and adjusting the parameters is straightforward.”

Question 6: What is your favorite iQon function?

Dr. Mahadeo Awale: “There are many functions eligible for the top spot. But I have to go with the feed curves because they are very useful. I set the feed curves once and iQon follows these curves without a hitch. I can also reimport the feed curves to use with the next flocks.”

Question 7: Do you occasionally use the remote support that Roxell offers? If so, what do you think of this service?

Dr. Mahadeo Awale: “During the installation phase, we requested help from Roxell’s support team with inputting certain parameters. Everything was done remotely and it went very quickly and smoothly.”

Interested in finding out what iQon can do for your poultry company? Contact a distributor in your country.