Safe and high-performance Roxell systems, certified worldwide

Roxell’s new products find their way to all 4 corners of the globe after their launch. The right safety certificates are what make our products real globetrotters.

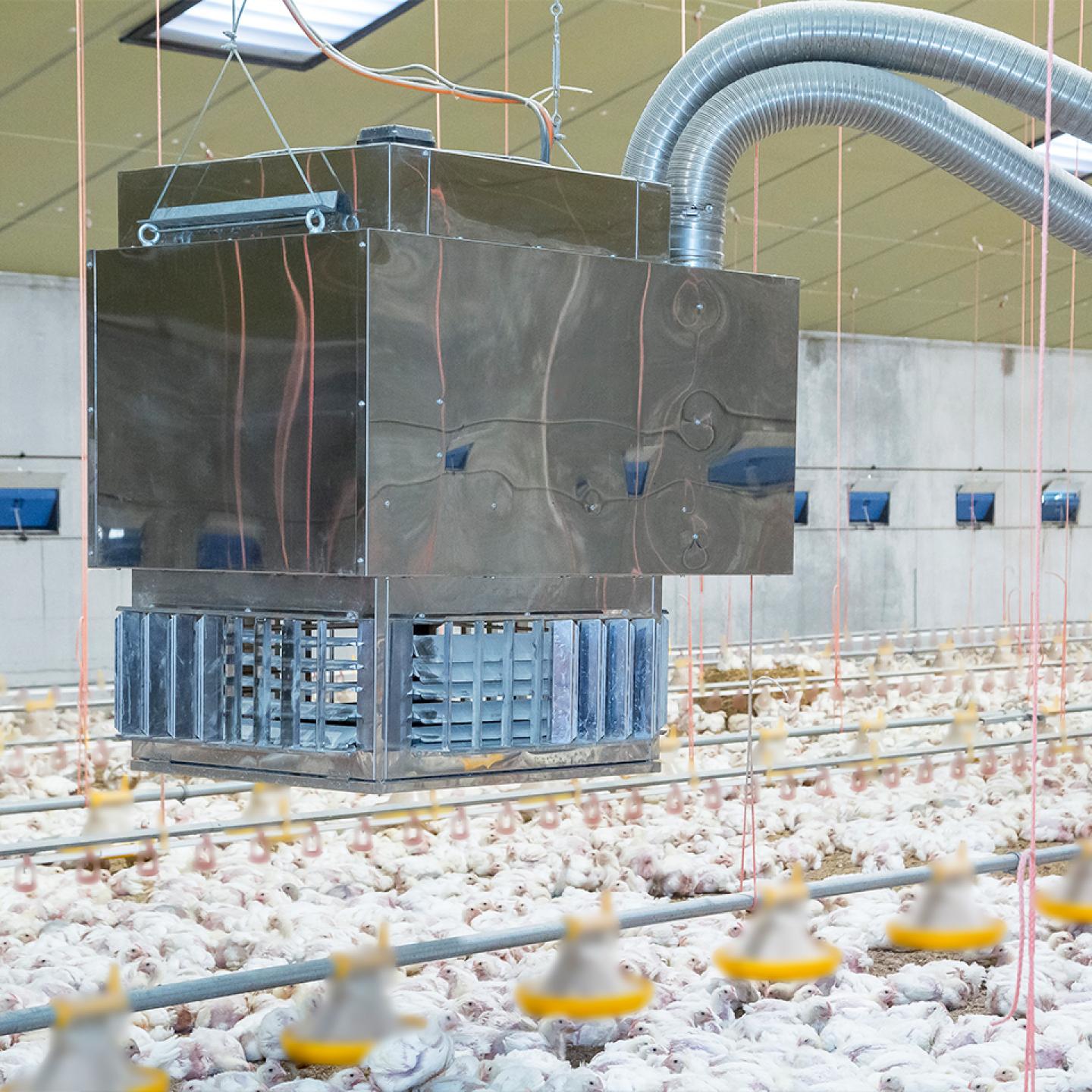

Due to the introduction of the new Siroc™ heating range our certification processes are working full steam ahead. We know that you expect only the safest products for the health of both humans and animals from a market leader like Roxell. This process is very involved. The criteria for a product to be certified for sale differs from region to region and is sometimes specific to one particular country. Susanna – our Certification Expert – ensures that new products can be sold all over the world when they are launched. Take a look behind the scenes at how we handle certification.

How does Roxell approach getting a product certified?

Susanna: “Months before the launch of a new product, we initiate the certification process for CE marking. This is a prerequiste for us to be able to sell in our ‘domestic markets’ in the European Economic Area (EEA). CE marking sets stringent requirements for safety and is therefore a good basis for certification outside of the EEA. Countries such as Russia, Australia, New Zealand and South Korea often have their own differing certification standards. The aim is to be able to offer our new systems in as many countries as possible after the launch.

Our heating appliances and feed bins require the most thorough risk analyses. But we seem to be doing very well. I’ve seen photos where our feed bins were the only thing still standing after a strong tornado. This to me is proof of the efficacy of our strict focus on safety and quality! Our business processes are well structured and that gives us a huge advantage during certification, since we never have to start from zero. There is already a strong foundation.”

What do auditors say about Roxell’s approach to safety?

Susanna: “We have two types of audits, one in the factory and one administrative audit. Auditors often comment that our technical documentation is very extensive and detailed. That offers our distributors and installers a huge advantage, and the poultry and pig farmers benefit from it too. After all, a well-installed system has a longer lifespan. Our approach to spare parts always scores highly during audits. We support our distributors fully when determining the critical spare parts.”

Susanna: “I take as many workshops and training courses on certification as I can. It’s necessary because safety criteria is always becoming stricter and/or more standardized. I also participate in the international certification meetings held by tekom, an organization that focuses on technical communication. In addition, I receive input on ‘what’s next’ from the Belgian technology organization Agoria. Therefore, I am always on top of any legislative amendments and that helps Roxell and its distributors anticipate changes.”