Roxell launches Fidos™ farrowing for better sow condition

Increase sows’ milk production with electronic feeding in the farrowing house. It gives piglets a great start in life, as they grow more consistently and reach a higher weaning weight.

Precise, individual feeding for higher milk production and optimal piglet growth

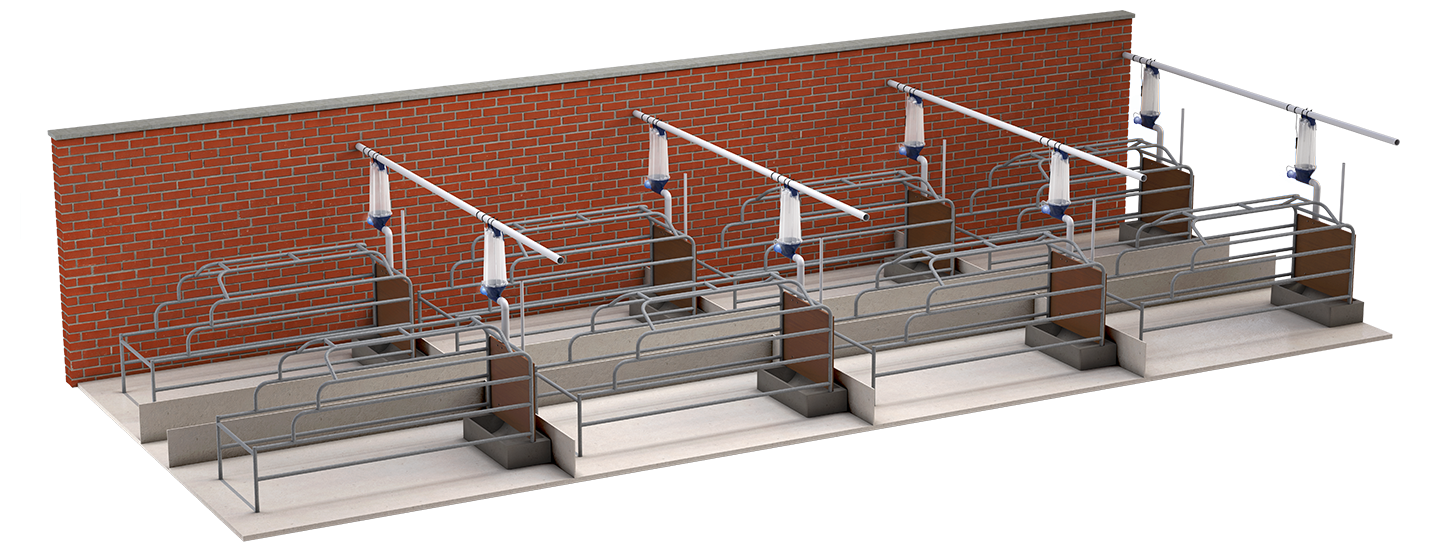

Roxell is expanding its Fidos™ range for electronic sow feeding. With Fidos farrowing, we are adding a smart dispenser to this feeding segment. This feeding system stimulates milk production, as it allows you to make adjustments according to the individual feed requirements of a sow. This results in piglets that grow more consistently and reach a higher weaning weight. This smart dispenser can also be used in the insemination house. In the gestation house — where sows live in groups — the smart Fidos feeding station is the best choice. Therefore, Fidos is the best feed solution for a better sow condition in every stage of the cycle.

A fit, stress-free sow means the piglets get the best start in life. The focus of Fidos farrowing is creating a fine-tuned eating process that stimulates milk production and keeps the sow at the right weight. Each individual farrowing pen is therefore fitted with a cone-shaped dispenser. This design provides the best guarantee that the feed ration will fully drop from the dispenser and that the sows can eat stress-free, without having to wait.

Based on your settings, Fidos farrowing will begin feeding at intervals. You can set the feed volume on a feed curve, which can be individually programmed for each sow. The volume increases automatically and gradually, so you have a fit and healthy sow at the end of the suckling period. You can also make adjustments as you go, as needed. Fidos therefore allows you to feed individually and with precision according to the needs of the animal.

You can also follow the trend of providing smaller rations at regular intervals in the farrowing house. You increase the daily feed volume, knowing that the sow will consume the extra feed. By feeding at regular intervals, the sow never feels as if she has overeaten and her energy and blood counts are stable. After every feed ration, the sow will drink, which means she will consume more water and ultimately produce more milk. A sufficient milk supply is the key to healthy piglets with uniform growth.

The dispenser drops feed at a slow rate for an eating speed of 200 grams per minute. This rate can also be adjusted. The feed is therefore always fresh. Whichever feed type you choose — mash or pellets — it will flow smoothly through the wide dispenser opening. You can provide the types of feed that your sows need.

Automation should be a tool to make your daily work easier. With Fidos farrowing, you no longer need to individually set the dispensers. The system centrally controls the feed quantities per day, per sow and according to their needs. If you want to adjust a sow’s feed curve during a daily inspection, you can do this with a handheld terminal with WiFi. You can scan the sow’s RFID ear tag and directly adjust the feed curve in the system.

These five tools improve the user-friendliness even further:

- The color of the LED light on the dispenser indicates the status of the motor. You can also have this signal display per compartment on a panel.

- The dosing auger of the dispenser automatically clears any potential blockages by rapidly moving back and forth up to three times.

- The large circumference of the dispenser opening prevents blockages with fine types of feed, such as mash.

- Due to the transparent body, you can quickly see what is happening inside the dispenser.

- Via a useful hatch on the front of the dispenser, you can insert additives and clean the inside.

Fidos farrowing is a tool for every sow farmer that can minimize manual work and save time when implementing a feed strategy. This tool helps generate quality results for your sows and piglets.

The data in Fidos can also be exported to a standardized format, so you can import it into smart applications.

Existing Roxell customers can also register and monitor the feed intake of sows in the farrowing house. It is possible to update the Dos7® dispenser without fully replacing it.